“连杆螺钉”加工工艺及Φ45一端工艺凸台设计

“连杆螺钉”加工工艺及Φ45一端工艺凸台设计

- 资源类别:论文

- 资源分类:机械机电

- 适用专业:机械制造工艺学

- 适用年级:高等院校机械专业

- 上传用户:362289077

- 文件格式:word+AutoCAD

- 文件大小:2.21MB

- 上传时间:2010/5/11 13:56:31

- 下载次数:3 次

- 浏览次数:441 次

资料简介

目录

1. 零件的分析......................................................................................2

1.2 零件的作用................................................................................2

1.3 零件的工艺分析........................................................................2

2. 工艺规程的设计..............................................................................2

2.1 确定毛坯的制造形式..................................................................2

2.2 基准的选择..................................................................................2

2.3 工艺路线的制定..........................................................................2

2.4 机械加工余量,工序尺寸及毛坯尺寸的确定...............................4

2.5确定切削用量及基本工时.............................................................5

3.铣直径45mm端尺寸为42mm的平面............................................13

4. 铣φ45外圆削边的夹具..................................................................14

4.1 问题的提出..................................................................................14

4.2 夹具的设计..................................................................................14

5. 夹具使用说明..................................................................................16

6. 铣工艺凸台夹具..............................................................................17

7. 夹紧机构.........................................................................................17

8. 加紧力的计算..................................................................................17

9. 操作的简要说明..............................................................................18

10. 结构分析.......................................................................................18

11. 小结...............................................................................................21

致谢

参考文献

有CAD夹具装配图,夹具体图,零件图,毛坯图,对刀块图,工序图,机械加工工艺卡片,工序卡片,拥有详细设计计算过程,课程设计任务书

1. 零件的分析......................................................................................2

1.2 零件的作用................................................................................2

1.3 零件的工艺分析........................................................................2

2. 工艺规程的设计..............................................................................2

2.1 确定毛坯的制造形式..................................................................2

2.2 基准的选择..................................................................................2

2.3 工艺路线的制定..........................................................................2

2.4 机械加工余量,工序尺寸及毛坯尺寸的确定...............................4

2.5确定切削用量及基本工时.............................................................5

3.铣直径45mm端尺寸为42mm的平面............................................13

4. 铣φ45外圆削边的夹具..................................................................14

4.1 问题的提出..................................................................................14

4.2 夹具的设计..................................................................................14

5. 夹具使用说明..................................................................................16

6. 铣工艺凸台夹具..............................................................................17

7. 夹紧机构.........................................................................................17

8. 加紧力的计算..................................................................................17

9. 操作的简要说明..............................................................................18

10. 结构分析.......................................................................................18

11. 小结...............................................................................................21

致谢

参考文献

有CAD夹具装配图,夹具体图,零件图,毛坯图,对刀块图,工序图,机械加工工艺卡片,工序卡片,拥有详细设计计算过程,课程设计任务书

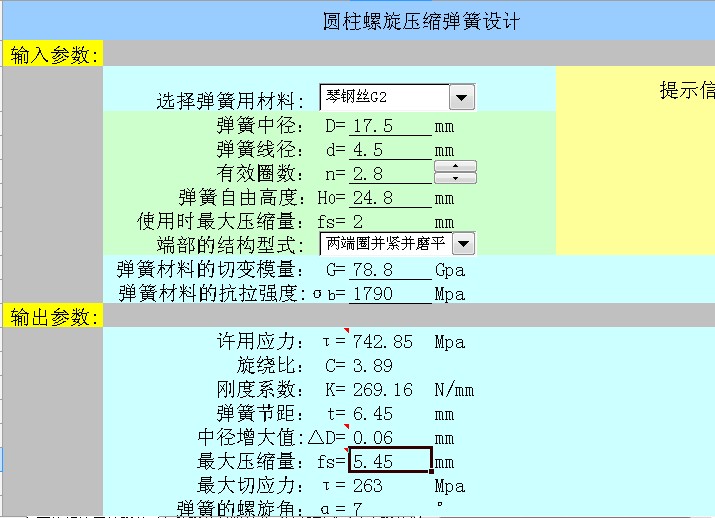

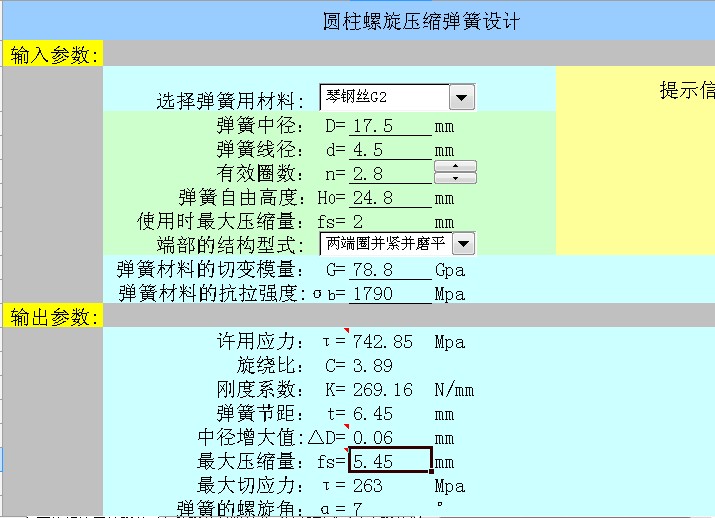

资料预览图片:

资料文件预览

共3文件夹,12个文件,文件总大小:3.29MB,压缩后大小:2.21MB

- “连杆螺钉”加工工艺及Φ45一端工艺凸台设计

- “连杆螺钉”加工工艺及Φ45一端工艺凸台工装夹具设计

A1夹具体.dwg [155.50KB]

A1夹具体.dwg [155.50KB] A1夹具装配图.dwg [85.00KB]

A1夹具装配图.dwg [85.00KB] A3毛坯图.dwg [79.50KB]

A3毛坯图.dwg [79.50KB] A3直角对刀块.dwg [129.38KB]

A3直角对刀块.dwg [129.38KB] A3零件图.dwg [152.78KB]

A3零件图.dwg [152.78KB] “连杆螺钉”加工工艺及Φ45一端工艺凸台工装夹具设计说明书.doc [229.50KB]

“连杆螺钉”加工工艺及Φ45一端工艺凸台工装夹具设计说明书.doc [229.50KB] 工序卡片.doc [588.50KB]

工序卡片.doc [588.50KB] 工序图.dwg [384.00KB]

工序图.dwg [384.00KB] 机械加工工艺卡片.doc [77.50KB]

机械加工工艺卡片.doc [77.50KB]- 课设任务书

File0003.Jpg [805.00KB]

File0003.Jpg [805.00KB] File0004.Jpg [678.75KB]

File0004.Jpg [678.75KB] Thumbs.db [7.00KB]

Thumbs.db [7.00KB]

下载地址

- [ “连杆螺钉”加工工艺及Φ45一端工艺凸台设计下载 ] (需要: 102 个学海币) 如何赚学海币

资料评论

注意事项

下载FAQ:

Q: 为什么我下载的文件打不开?

A: 本站所有资源如无特殊说明,解压密码都是www.xuehai.net,如果无法解压,请下载最新的WinRAR软件。

Q: 我的学海币不多了,如何获取学海币?

A: 上传优质资源可以获取学海币,详细见学海币规则。

Q: 为什么我下载不了,但学海币却被扣了?

A: 由于下载人数众多,下载服务器做了并发的限制。请稍后再试,48小时内多次下载不会重复扣学海币。

下载本文件意味着您已经同意遵守以下协议

1. 文件的所有权益归上传用户所有。

2. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

3. 学海网仅提供交流平台,并不能对任何下载内容负责。

4. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

5. 本站不保证提供的下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

Q: 为什么我下载的文件打不开?

A: 本站所有资源如无特殊说明,解压密码都是www.xuehai.net,如果无法解压,请下载最新的WinRAR软件。

Q: 我的学海币不多了,如何获取学海币?

A: 上传优质资源可以获取学海币,详细见学海币规则。

Q: 为什么我下载不了,但学海币却被扣了?

A: 由于下载人数众多,下载服务器做了并发的限制。请稍后再试,48小时内多次下载不会重复扣学海币。

下载本文件意味着您已经同意遵守以下协议

1. 文件的所有权益归上传用户所有。

2. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

3. 学海网仅提供交流平台,并不能对任何下载内容负责。

4. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

5. 本站不保证提供的下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。